Leistungssteigerung mit Ölkühleranschlüssen

Im Automobil- und Industriesektor Ölkühlerarmaturen spielen eine entscheidende Rolle für optimale Motorleistung und Langlebigkeit. Diese kleinen, aber wichtigen Komponenten verbinden Ölkühler mit dem Motor, sorgen für eine effiziente Wärmeableitung und schützen vor Überhitzung des Motors.

Die Bedeutung von Ölkühleranschlüssen

Ölkühleranschlüsse erleichtern den Ölfluss zwischen Motor und Ölkühler. Hochwertige Anschlüsse sind entscheidend für die Integrität des Ölkühlsystems. Schlechte Qualität oder schlecht installierte Anschlüsse können zu Öllecks, Druckabfall und sogar Motorschäden führen. Zuverlässige und langlebige Anschlüsse sind unerlässlich für einen gleichmäßigen Ölfluss und eine effektive Wärmeübertragung.

Arten von Ölkühleranschlüssen

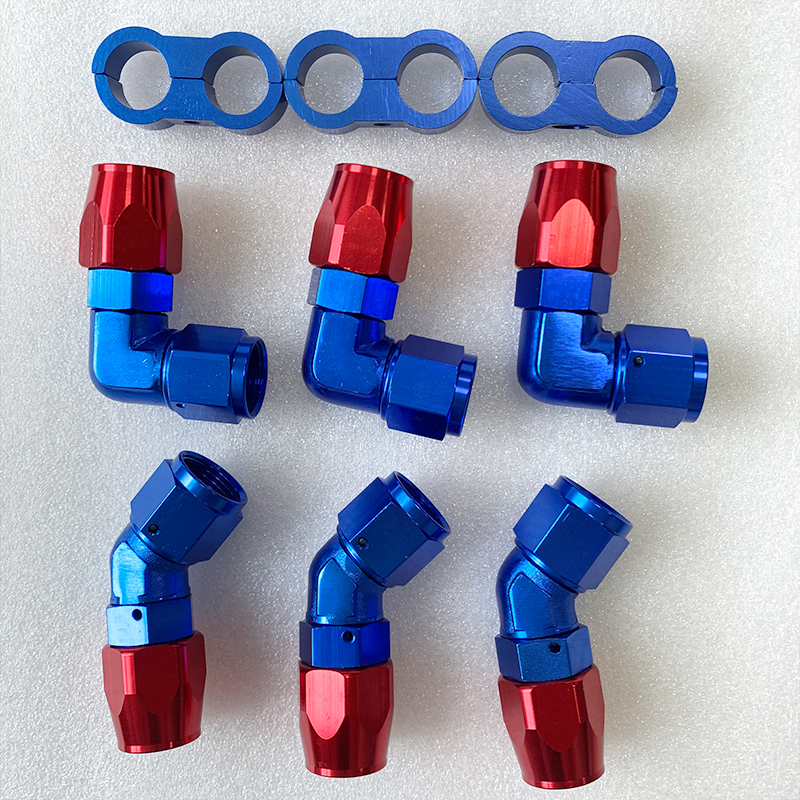

1. AN-Armaturen

AN-Armaturen werden aufgrund ihrer Langlebigkeit und Zuverlässigkeit häufig verwendet. Sie sind in verschiedenen Größen erhältlich und für Hochdruckanwendungen geeignet. Das AN-Armaturensystem zeichnet sich durch sein ausgestelltes Design aus, das eine sichere Verbindung gewährleistet und das Risiko von Leckagen minimiert.

2. O-Ring-Boss-Anschlüsse (ORB)

ORB-Anschlüsse dichten mit einem O-Ring ab. Sie werden aufgrund ihrer einfachen Installation und Kompatibilität mit verschiedenen Materialien häufig in der Automobilindustrie eingesetzt. ORB-Anschlüsse eignen sich ideal für Nieder- bis Mitteldrucksysteme.

3. Klemmverschraubungen

Klemmringverschraubungen sind für ihre einfache Installation und die leckagefreie Verbindung bekannt. Sie verwenden eine Klemmhülse, die gegen das Rohr gedrückt wird und so eine dichte Abdichtung erzeugt. Diese Verschraubungen eignen sich für verschiedene Rohrmaterialien und werden häufig in hydraulischen und pneumatischen Systemen eingesetzt.

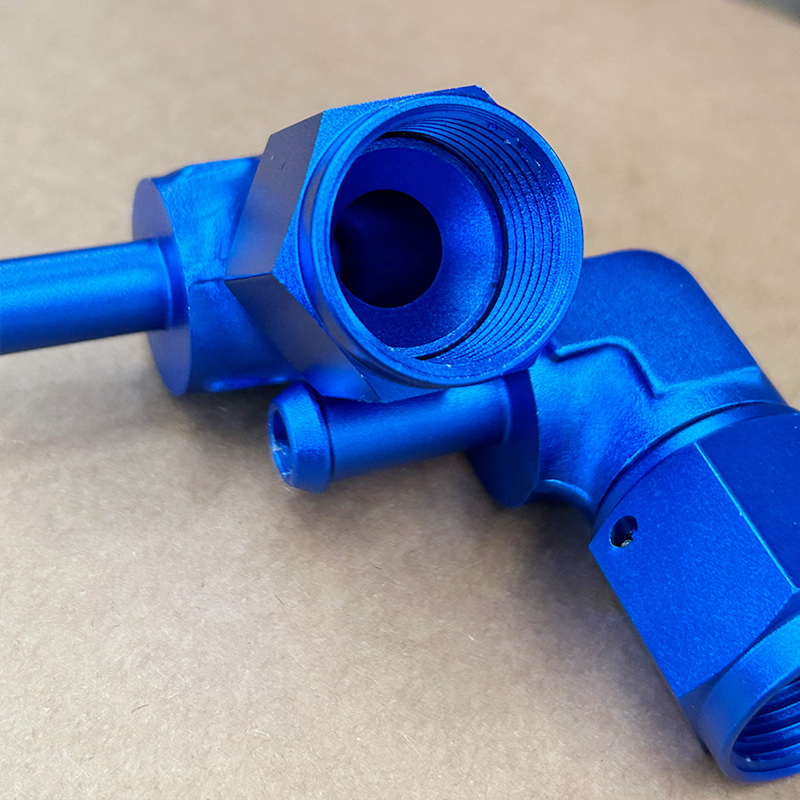

4. Mehrschichtige Ölkühleranschlüsse

Das mehrschichtige Design der Ölkühlerarmatur verbessert die Dichtleistung. Ein Dichtring und eine federbelastete Dichtung gewährleisten eine zuverlässige Abdichtung auch unter Hochdruckbedingungen. Der mehrschichtige Aufbau bietet mehrschichtigen Schutz vor Leckagen und Verunreinigungen.

Auswahl der richtigen Ölkühleranschlüsse

Berücksichtigen Sie bei der Auswahl von Ölkühleranschlüssen die folgenden Faktoren:

Hochwertige Ölkühleranschlüsse sind für effiziente Ölkühlsysteme unerlässlich. Ob AN-Anschlüsse, ORB-Anschlüsse, Klemmverschraubungen oder geschichtete Ölkühleranschlüsse – die Auswahl des richtigen Typs und die ordnungsgemäße Installation sind entscheidend für optimale Motorleistung und Langlebigkeit.

Durch die Investition in zuverlässige Ölkühlerarmaturen können Sie die Effizienz Ihres Ölkühlsystems verbessern und Ihren Motor vor Überhitzung und Verschleiß schützen.

Wir senden Ihnen unseren Katalog zur Einsicht zu, der alle Armaturentypen enthält, die Sie interessieren. Wenn Sie Muster benötigen, können Sie sich gerne an mich wenden.