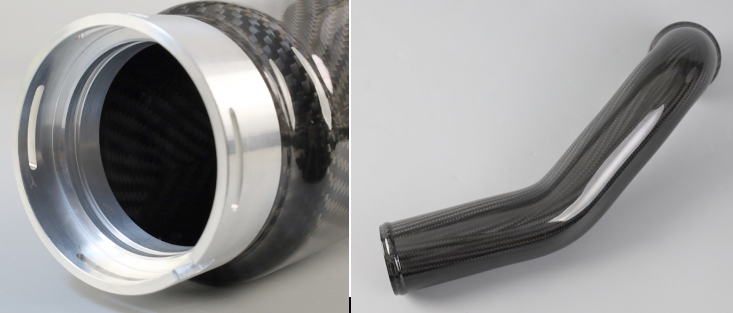

Maßgefertigte Aluminiumrohre bis hin zu Kohlefasermaterial

Im Vergleich zu herkömmlichen Metallrohren (wie z. B. Aluminium- und StahlrohreDer Hauptvorteil von Kohlenstofffaserrohren beruht auf ihren Verbundwerkstoffeigenschaften und ihrer Anisotropie (d. h. unterschiedlichen Eigenschaften in verschiedenen Richtungen). Im Folgenden sind einige ihrer wichtigsten Vorteile aufgeführt:

Das ist der bedeutendste Vorteil.

Daten: Kohlenstofffasern haben eine Dichte von ca. 1,6 g/cm³, im Vergleich zu ca. 2,7 g/cm³ bei Aluminium.

Vorteil: Bei gleicher Steifigkeit kann ein Kohlefaserrohr 40–60 % leichter sein. Umgekehrt ist ein Kohlefaserrohr bei gleichem Gewicht deutlich fester und steifer, insbesondere in axialer Richtung. Dies führt zu verbesserter Beschleunigung, höherer Energieeffizienz und größerer Nutzlastkapazität in Anwendungen wie Luft- und Raumfahrt, Drohnen und Hochleistungsfahrzeugen.

Vorteil: Kohlenstofffaserverbundwerkstoffe weisen eine deutlich höhere Dauerfestigkeit als Aluminium auf. Sie sind weniger anfällig für Rissausbreitung unter wiederholten Belastungszyklen (z. B. Vibration, Biegung).

Vorteil: Kohlenstofffaser ist inert und rostet oder korrodiert nicht wie Aluminium. Sie eignet sich hervorragend für raue Umgebungen, einschließlich des Kontakts mit Salzwasser, Chemikalien und Feuchtigkeit, wodurch eine schützende Anodisierung oder Beschichtung überflüssig wird.

5. Die Kosten sind ebenfalls deutlich gesunken, und je mehr man kauft, desto kostengünstiger wird es.

6. Kundenspezifische Anforderungen wie Logo, Verpackung etc. sind möglich. Jagrow kann neue Kohlefaserteile nach Zeichnungen/Mustern entwickeln.

Sie können gerne Kontaktieren Sie uns falls Sie spezielle Wünsche haben.